Taking Flight with CAD/CAM

Taking Flight with CAD/CAM: Revolutionizing Aerospace Design

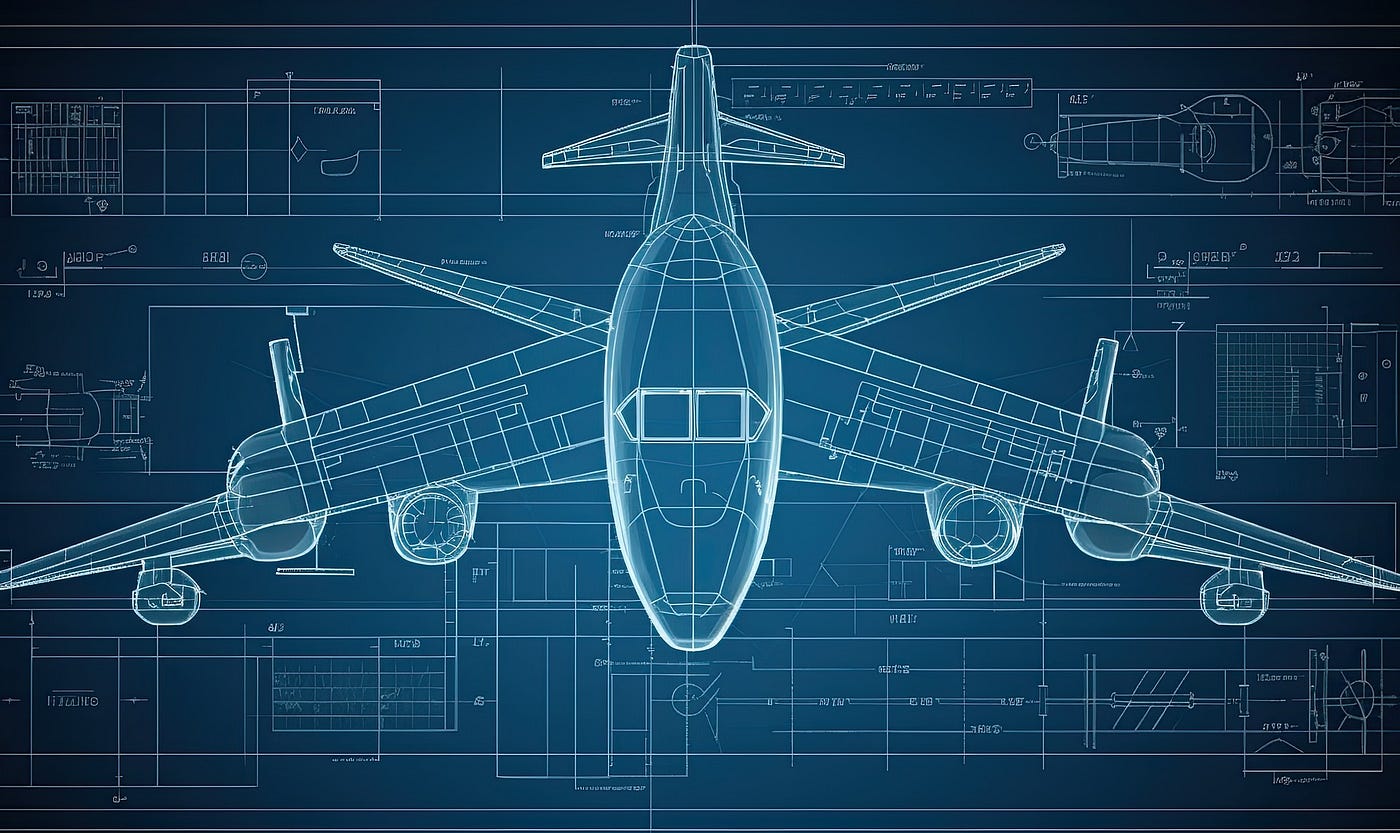

The relentless pursuit of innovation and efficiency defines the aerospace industry. Every design decision impacts an aircraft's performance, fuel consumption, and ultimately, its ability to conquer the skies. Here's where CAD/CAM software soars as an indispensable tool, empowering engineers to craft the marvels of modern aviation with unparalleled precision and efficiency.

CAD: Propelling Design into the Digital Age

From Sketchpad to Digital Wind Tunnel: Gone are the days of hand-drawn blueprints. CAD software allows aerospace engineers to create detailed 3D models of airplanes, rockets, and spacecraft. These virtual models come alive with features like Computational Fluid Dynamics (CFD) simulations. Imagine digitally replicating wind tunnel tests, analyzing airflow over wings and entire aircraft configurations. This empowers engineers to optimize wing design for minimal drag, maximizing fuel efficiency and flight range.

Lightweighting the Skies: Every gram counts in aerospace. CAD software goes beyond visualization. Features like generative design explore countless design variations based on pre-defined parameters like strength and weight constraints. This allows engineers to identify the lightest and strongest configurations for each part, from complex wing structures to intricate engine components. This translates to increased fuel efficiency, allowing aircraft to fly farther with heavier payloads.

Perfect Fit, Guaranteed: Assembling a complex aircraft requires components to fit together with micrometer precision. CAD software facilitates this by enabling the creation of digital mockups of the entire aircraft, complete with detailed 3D models of every part. Engineers can virtually assemble the aircraft in a digital environment, identifying potential clearance issues or design clashes before a single metal sheet is cut. This streamlines the manufacturing process and ensures a perfect final product, eliminating costly delays and rework.

CAM: The Invisible Hand of Precision Manufacturing

Precision Takes Flight: CNC machining, guided by meticulously generated CAM toolpaths, ensures parts are manufactured with unmatched precision. This is crucial for critical components like landing gear assemblies, flight control systems, and intricate engine parts. Even the most complex geometries and tight tolerances are replicated flawlessly, guaranteeing the safety and performance of the aircraft.

Optimizing Every Cut: Every gram of material saved in an airplane translates to significant fuel savings over an aircraft's lifetime. CAM software analyzes 3D models and generates highly efficient toolpaths that minimize material waste during the machining process. This not only reduces costs but also contributes to a more sustainable aerospace industry. Imagine a program that calculates the most efficient way to remove material from a complex turbine blade, minimizing waste and saving precious resources.

Virtual Test Flights Before Takeoff: Advanced CAM software offers simulation capabilities beyond just toolpath generation. Engineers can create a digital representation of the entire manufacturing process, identifying potential problems like tool collisions or machining inefficiencies before they occur on real machines. This proactive approach saves time, money, and wasted material. Imagine virtually testing an entire machining sequence for a complex rocket engine component, identifying and eliminating potential issues before production begins.

The Future: Soaring to New Heights with Innovation

The integration of CAD/CAM software has revolutionized aerospace design. It has ushered in an era of:

Faster Design Cycles: The ability to iterate quickly and virtually eliminate physical prototypes leads to significantly faster aircraft design cycles. This allows engineers to bring innovative concepts to life quicker, getting cutting-edge technology into the skies sooner.

Enhanced Aircraft Performance: Advanced simulations and lightweight design optimization lead to aircraft with improved fuel efficiency, longer ranges, and increased payload capacity. This translates to more sustainable air travel and the ability to explore further reaches of space.

Reduced Development Costs: From minimizing material waste to optimizing manufacturing processes, CAD/CAM software offers substantial cost savings throughout the aerospace design and production lifecycle. This allows for more efficient resource allocation and investment in future innovations.

As technology continues to evolve, we can expect even more powerful and integrated CAD/CAM solutions. Imagine AI-powered design tools that suggest optimal configurations based on performance goals and manufacturing constraints. The future of aerospace design is undoubtedly digital, with CAD/CAM software at the forefront, empowering engineers to create the next generation of groundbreaking aircraft that will redefine the boundaries of flight.

Nice work

ReplyDeleteNicely Done

ReplyDelete