How CAD/CAM Drives Innovation in Automotive Design

Revolutionizing the Road: How CAD/CAM Drives Innovation in Automotive Design

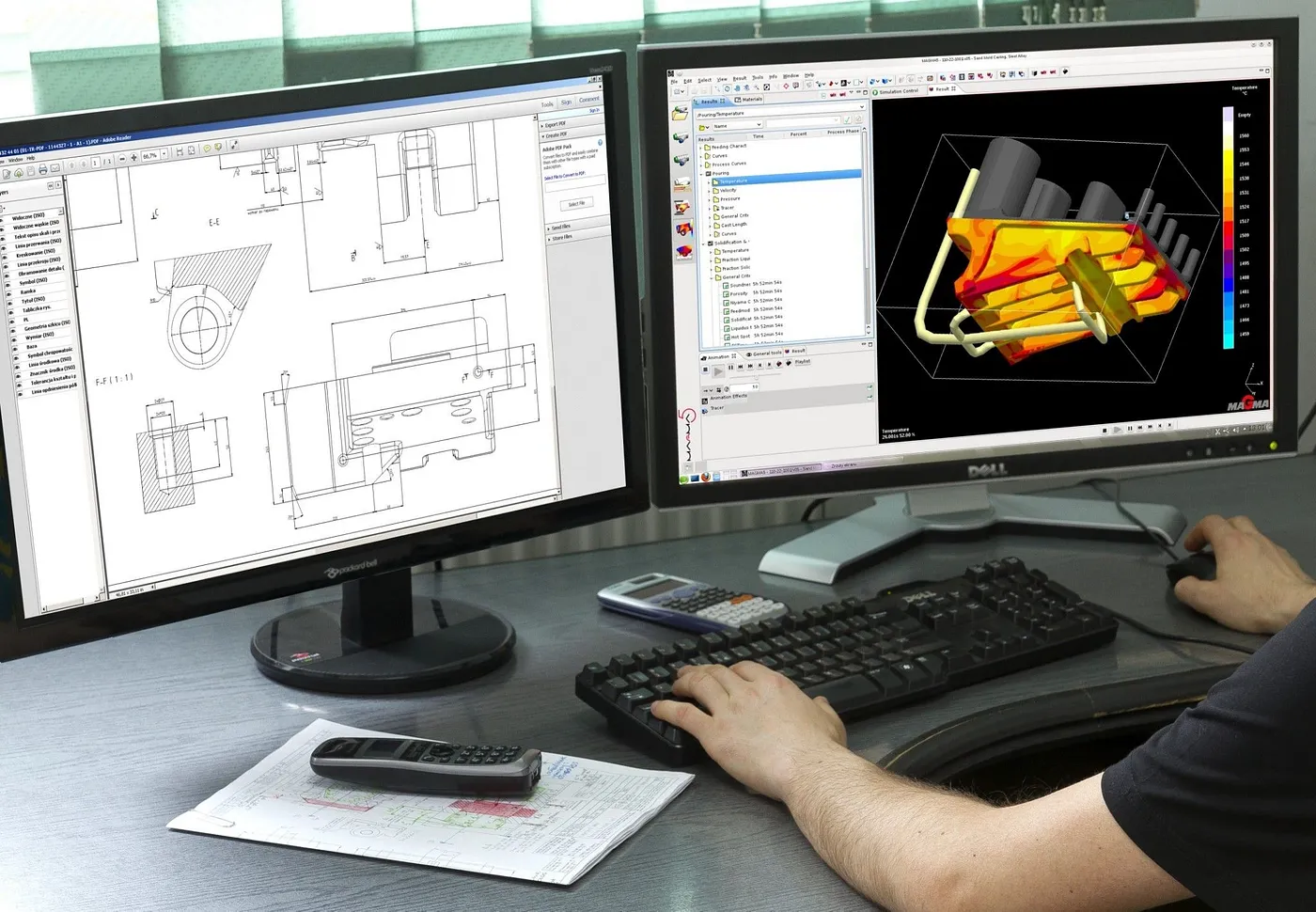

The automotive industry is a fascinating dance between artistry and engineering. Every head-turning design, every exhilarating performance, is the culmination of a meticulous process fueled by cutting-edge technology. CAD/CAM software plays a pivotal role in this process, transforming initial concepts into the vehicles that grace our roads. Let's delve deeper into how CAD/CAM software revolutionizes automotive design:

CAD: From Humble Sketch to Digital Showroom

Beyond Visualization: Shaping the Future in 3D: Gone are the days of drafting boards and painstakingly hand-crafted clay models. CAD software empowers automotive designers to create stunning 3D models of vehicles. These digital models come alive, allowing for 360-degree visualization and exploration of design concepts in unparalleled detail. Imagine rotating a virtual car on your screen, experimenting with different body styles like the aggressive curves of a Ford Mustang or the sleek lines of a Tesla Model S. You can add intricate aerodynamic features like the active rear wing of the McLaren 720S or even dissect the interior layout to optimize passenger space and comfort, all before a single sheet of metal is cut. This empowers designers to iterate quickly, explore a wider range of possibilities, and arrive at the optimal design much faster.

Collaboration on the Fast Track: The automotive design process is a symphony of collaboration – designers, engineers, manufacturing specialists, and even marketing teams all play a crucial role. CAD software facilitates this by enabling seamless teamwork across geographical boundaries. Real-time updates and shared access to 3D models ensure everyone is on the same page. Designers can incorporate feedback from engineers regarding manufacturability, for instance, suggesting alternative materials or simplifying complex shapes for easier production. Marketing teams can visualize the final product with features like configurable paint colors and interior trim options, well before production begins. This streamlined communication fosters faster design iterations and efficient decision-making.

Simulating Success: Virtual Test Drives Before Real Ones: Advanced CAD software boasts features like kinematic and dynamic simulations. These simulations are game-changers in the automotive design world. Engineers can virtually test a car's suspension system, steering response, and even crashworthiness long before a physical prototype is built. Imagine simulating how a car like the Jeep Wrangler handles a sharp turn on a rocky off-road trail or how a Toyota Corolla absorbs impact in a collision scenario. This allows engineers to identify potential issues early in the design process, optimize the design for superior performance and safety, and minimize the need for expensive physical prototypes.

CAM: The Invisible Hand of Manufacturing Precision

Precision on Wheels: From Digital Model to Flawless Part: Once the design is finalized in CAD, CAM software takes the wheel. It translates the intricate 3D geometry of the car's components, like a complex engine block or a sleek headlight assembly, into machine-readable instructions understood by CNC machines, robots, and automated assembly lines used in automotive manufacturing. This eliminates human error in programming toolpaths, resulting in parts produced with unmatched precision and consistent quality. Imagine a complex engine block with intricate cooling channels being machined with pinpoint accuracy, ensuring flawless operation and optimal performance throughout the engine's lifespan.

The Art of Efficiency: Minimizing Waste, Maximizing Savings: Every car part counts, and material waste can significantly impact production costs. CAM software analyzes 3D models and generates highly optimized toolpaths that minimize material waste during the machining process. This translates to significant cost savings for manufacturers, especially when dealing with expensive materials like carbon fiber used in high-performance vehicles or lightweight aluminum alloys increasingly common for fuel efficiency. Imagine a program calculating the most efficient way to cut out a car door panel from a large sheet of metal, minimizing scrap and maximizing material utilization. This not only reduces costs but also contributes to a more sustainable manufacturing process.

Quality Control on Autopilot: Ensuring Flawless Manufacturing: Modern CAM software integrates seamlessly with automated quality control systems. These systems use sensors and vision technology to inspect manufactured parts for any discrepancies compared to the digital 3D model. This proactive approach ensures consistent quality throughout the production process, minimizing the risk of defective parts reaching the assembly line. Imagine a robotic arm equipped with a high-resolution camera inspecting a car door for any imperfections in the weld seams or paint finish of a car like the BMW X7. This catches potential flaws early on, saving time and resources that would have been wasted fixing defective parts later in the production cycle.

Interesting 😊

ReplyDeleteVery Informative 😃

ReplyDelete